Optical Character Recognition (OCR) in Manufacturing – A Complete Guide

With accuracy upto 99%, optical character recognition (OCR) has become an invaluable tech. And OCR for manufacturing industry, well it is one of the most important tech. Just like those handy project management tools.

The industry eagerly wants to digitize documents and accelerate data extraction for streamlined operations.

Today’s guide is comprehensive and covers everything manufacturers like your need to know about applying OCR.

Whether you are new to OCR or looking to expand existing capabilities, this guide provides an in-depth look. Such as how OCR in manufacturing work, the benefits of OCR in manufacturing, and key use cases in manufacturing. Ultimately, you will get extensive insights and recommendations.

Let us begin.

What is OCR?

OCR refers to technology that can automatically recognize text and characters within digital images or scanned documents and convert them into machine-readable, editable, and searchable formats like Word, Excel, or PDF.

Instead of manually typing information from physical documents, OCR software analyzes document images and uses pattern recognition algorithms and dictionaries to identify the corresponding text characters.

This enables scanning paper documents and instantly converting them into editable digital files. The digitized copies can then be searched, edited, shared, and processed like any other digital document.

Core Stages of OCR Processing

A typical OCR process involves three core stages:

Image Preprocessing

The scanned image is prepared for analysis by techniques like:

- Noise removal – Eliminates scanning artifacts or specks.

- Skew correction – Straightens crooked pages and aligns text lines.

- Contrast enhancement – Sharpens and darkens text for easy recognition.

- Scaling – Standardizes font sizes across documents.

- De-speckling – Removes dots and specks that could be misrecognized as characters.

- Binarization – Converts images to black & white.

These improve image quality for more accurate text extraction.

Text Localization and Segmentation

The OCR engine detects text areas, columns, paragraphs, lines, words, and characters by identifying changes in pixel properties.

Text and non-text areas are separated by determining connected pixel regions with common alignment, spacing, and orientations.

Advanced algorithms can detect multiple zones on complex documents like forms.

Character Recognition

Machine learning algorithms analyze the pre-processed text images and extract each character using pattern recognition and computer vision techniques like:

- Feature extraction – Identify distinguishing features like lines, loops, and dots in characters.

- Classification – Compare extracted features against labeled example characters to identify the most likely match.

- Context analysis – Use surrounding text and dictionaries to improve ambiguous character predictions.

- Post-processing – Refine extracted text formatting, structure etc.

The output is a document with machine-readable text mapped to each section.

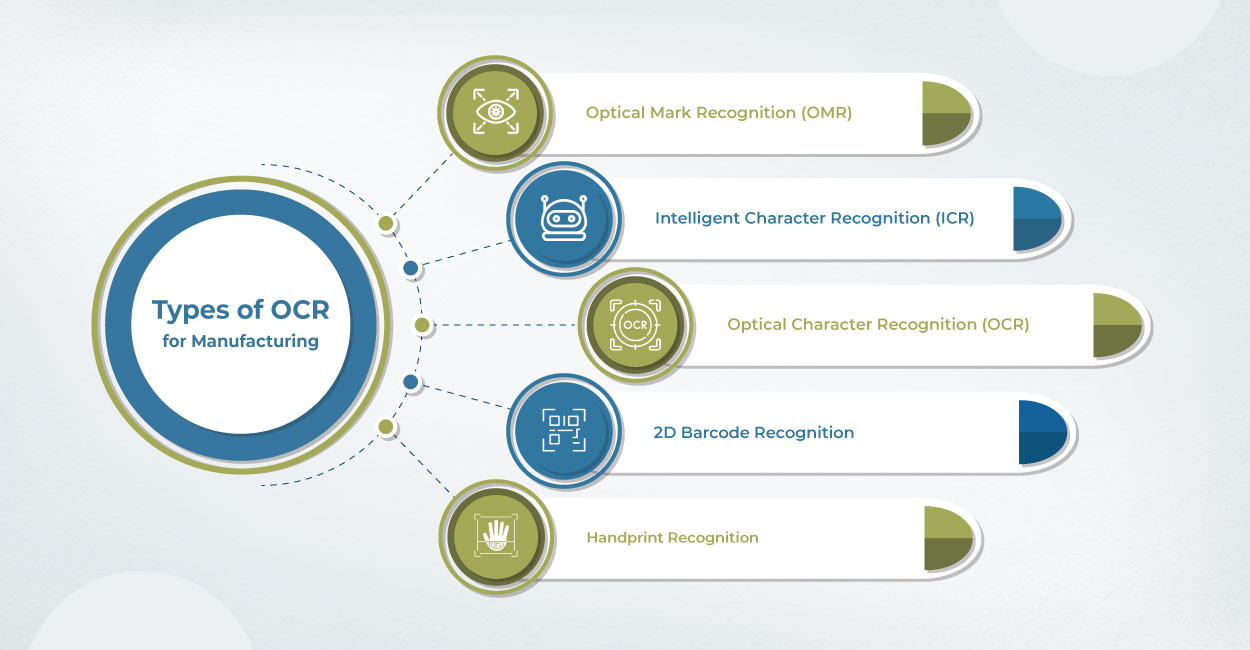

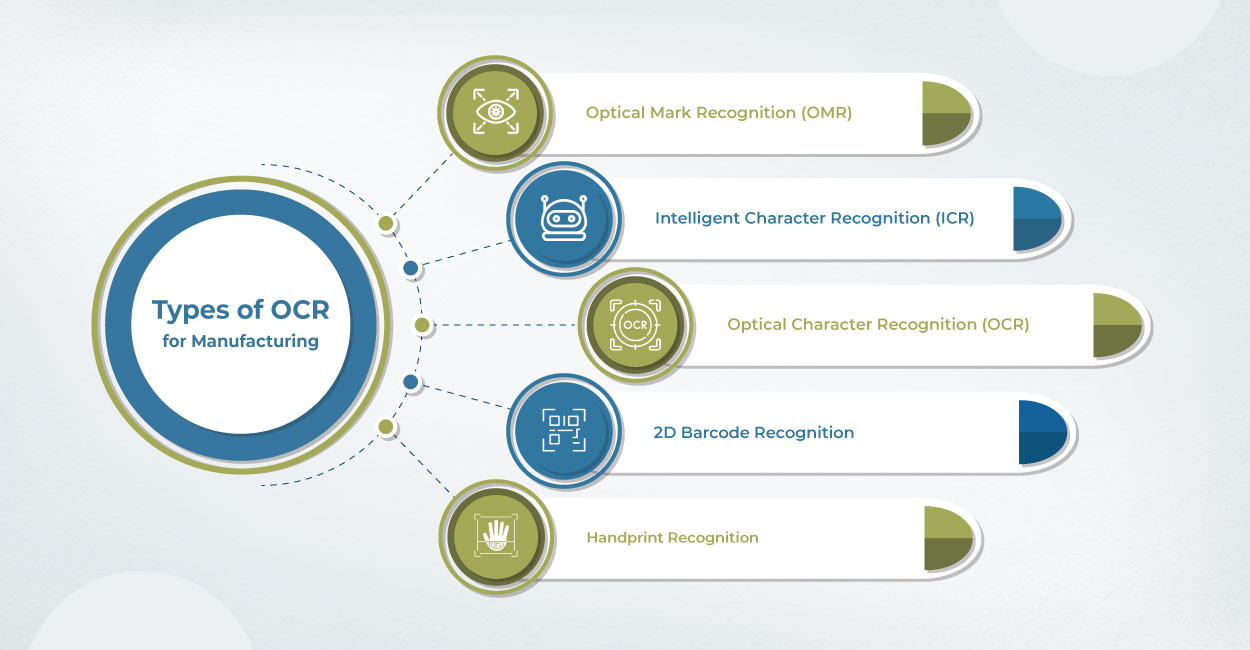

Types of OCR for Manufacturing

There are a few specific types of OCR technologies suited for manufacturing:

There are a few specific types of OCR technologies suited for manufacturing:

Optical Mark Recognition (OMR)

Recognizes pencil or pen markings like checkboxes, bubbles, grids, and barcodes on documents. Commonly used for fast form processing and data collection.

Intelligent Character Recognition (ICR)

Reads machine-printed or handwritten cursive texts one character at a time. Useful for unstructured documents containing annotations.

Optical Character Recognition (OCR)

Recognizes machine printed texts by words or characters. Most widely used OCR type for digitizing printed records and documents.

2D Barcode Recognition

Decodes data encoded within 2D barcodes like QR codes, Data Matrix, PDF417 etc. on product packaging and assets.

Handprint Recognition

Reads machine printed or handwritten texts with a higher focus on extracting handwritten inputs like signatures, log notes etc.

Key Benefits of OCR for Manufacturing

OCR provides major productivity, accuracy, compliance, and cost benefits:

Automates Document Processing

OCR eliminates slow and error-prone manual document re-entry by automatically extracting printed text to digital formats. This boosts data processing throughput exponentially.

Enhances Data Accuracy

Manual document processing has high error rates. OCR removes human errors in interpretation and rekeying to improve data reliability.

Digitizes Legacy Document Archives

Vast paper records and old engineering drawings can be digitized using OCR for easier archival and retrieval.

Simplifies Regulatory Compliance

OCR provides digital audit trails for document processing procedures required for compliance standards like ISO, GDPR, HIPAA etc.

Boosts Productivity

Workers save significant time by avoiding manual document handling. This allows reallocating human effort to more value-adding tasks.

Reduces Operational Costs

OCR reduces document processing costs by over 80% compared to fully manual methods as per leading research.

Enhances Searchability

OCR enables full-text search within scanned document images for faster information discovery.

Improves Data Analysis

Digitized documents can be processed and mined using data analytics and machine learning for hidden insights.

Simplifies Document Collaboration

Editable OCR digitized files allow easier sharing across teams and locations compared to scanned images.

OCR Challenges and Limitations

While promising, OCR usage in manufacturing still faces some technology limitations:

- Scanner Image Quality – Scanning inconsistencies like noise, blur, skew etc. can impact OCR accuracy.

- Handwritten Texts – Handwritten annotations and inputs are harder to recognize accurately versus printed text.

- Complex Document Layouts – Multi-column formats, tables, graphics, and curved text disorient OCR engines.

- Fonts and Styling – Stylized and decorative fonts, italics, and letterspacing create ambiguity.

- Low-quality Originals – Faded prints, carbon copies, and low-contrast documents are tougher.

- Substrate Challenges – Glossy, reflective, or textured document surfaces pose additional problems.

- Foreign Languages – Unicode character sets and right-to-left languages like Arabic require specialized training.

- Data Formatting – Additional post-processing is needed to extract information into spreadsheets.

However, AI and deep learning techniques are helping overcome many of these limitations.

Impact of AI and Machine Learning on OCR

Traditional OCR relied on manually created rules and patterns for character recognition. But AI and deep learning allow “smart” OCR systems:

Automatic Pattern Learning

Neural networks automatically identify distinguishing features in text images during the training process. This eliminates manual feature engineering.

Self-Improving Models

Deep learning models continuously retrain on new data. This allows improving recognition accuracy automatically over time.

Contextual Understanding

AI techniques like natural language processing enable using document structure, grammar, and vocabulary to resolve ambiguities.

Multilingual Support

Large pre-trained language models can be fine-tuned to identify text in different languages without re-engineering.

Data Labeling

Semi-supervised learning reduces manual data labeling requirements for deep learning.

Adapting to Variations

AI models are more robust when handling document variations, noise, fonts, sizes etc. compared to rules-based techniques.

In essence, AI allows creating accurate and flexible “universal OCR engines” versus limited-scope solutions.

Key Considerations for Choosing OCR Approaches

Selecting the optimal OCR technique involves assessing:

- Printed vs. Handwritten Text – Handwritten text requires AI-based ICR/HPR engines versus traditional OCR.

- Document Quality – Poor quality needs enhanced preprocessing versus good quality scans.

- Language Support – Multilingual documents require AI-based engines trained on multiple languages.

- Output Requirements – Formatting like PDF vs. spreadsheets impacts engine choice.

- Integration Effort – Tighter integration may dictate custom coding versus ready APIs.

- Implementation Time – Pre-trained cloud APIs are faster to launch versus custom models.

- Security – Public cloud options may not suit sensitive documents versus on-premise tools.

- Cost – Cloud solutions require weighing uptime versus throughput charges.

OCR Implementation Best Practices

To maximize success, OCR programs need:

- Image Optimization – Standardize scanning profiles and enhance images.

- Data Validation – Spot-check outputs to measure and improve accuracy.

- Workflow Integration – Incorporate OCR seamlessly within document processing workflows.

- Model Governance – Monitor model drift; trigger retraining when needed.

- Staff Training – Invest in operator training for optimal scanning practices.

- Output Structuring – Use parsers or natural language processing to structure flat OCR text outputs.

- Automation – Automate recurring OCR tasks through scripts or bots.

- Curation – Maintain datasets, models, metrics etc. for reusability and consistency.

- Compliance Controls – Add security, access controls, audits etc. to satisfy regulations.

- Monitoring – Track OCR reliability with KPIs like accuracy, cycle times etc.

- Backup Procedures – Set up backups and recovery mechanisms for busines continuity.

Getting OCR implementations right requires upfront planning and investment. But the long-term efficiency gains are substantial.

Major Use Cases for OCR in Manufacturing

OCR for manufacturing offers a range of applications:

Production and Asset Records

OCR can extract text from production reports, process logs, maintenance work orders, calibration forms etc. into databases. This structured data can then fuel analytics.

Inventory and Warehouse Documents

Pick lists, shipping manifests, logistics records, and inventory forms contain valuable structured data that OCR can automatically digitize.

Supplier and Vendor Documents

Purchase orders, invoices, delivery receipts, and bills of lading received from suppliers in various formats can be standardized using OCR.

Product Specification Sheets

Product spec sheets, datasheets, certificates etc. can be processed by OCR to extract key parameters into product databases.

Operator Instruction Cards

Graphics-heavy work instructions on factory floors can integrate text snippets recognized by OCR for smart retrieval and digital delivery.

Warranty and Repair Forms

End customer warranty forms and service technician repair logs contain useful structurable data extractable by OCR.

Blueprint and Schematic Archives

Legacy hand-drawn engineering drawings and schematics can be digitized using specialized OCR techniques.

IoT Data Capture

OCR can extract readings from analog meters, gauges, etc. for automating IoT data capture from factory devices.

Document Search and Retrieval

OCR in manufacturing enables full-text search of legacy scanned documents in repositories for faster information discovery.

Automated Data Entry

Operator logbooks, audit records, time sheets etc. can eliminate manual re-entry by directly capturing handwritten text with OCR.

These applications demonstrate the versatility of OCR in optimizing document-driven manufacturing workflows.

Getting Started with OCR

OCR in manufacturing can provide a competitive edge by enhancing document processing efficiency. To embark on an OCR automation journey:

Evaluate business impact – Identify processes slowing down due to manual document handling.

Assess digitization needs – Catalog key document types, formats, and information needs.

Analyze required accuracy – Determine acceptable accuracy levels for each document type.

Select optimal techniques – Shortlist AI-based and/or rules-based approaches per use case.

Develop a pilot – Start with a limited pilot to quantify potential ROI.

Partner with experts – Work with experienced OCR implementation partners like Beyond Key.

Plan for the future – Architect long-term scalability into solutions.

With the right strategy, OCR for manufacturing can drive step-function improvements in document workflows. The time to explore OCR automation is now.

Beyond Key’s OCR is Perfect for Manufacturing

As we saw, the benefits of OCR in manufacturing are many. Provides manufacturing companies with immense opportunities to eliminate slow and costly manual document processing.

With advances in AI and deep learning, OCR accuracy and flexibility have improved exponentially to make large-scale automation viable.

So transform your document workflows with Beyond Key’s AI-powered OCR for manufacturing services. Our solutions deliver over 98% accuracy by leveraging advanced neural networks trained on millions of text samples.

We handle any document type or format seamlessly. Our secure cloud infrastructure enables scaling OCR workloads instantly. With round-the-clock support and continuous enhancements, we help you consistently extract maximum value from OCR technology.

Partner with the experts who’ve processed millions of documents globally. Accelerate your business productivity and insights with Beyond Key’s trusted OCR in manufacturing services.

Wrapping Up

By selecting optimal OCR approaches per document type and investing in robust implementation, manufacturers can reap substantial benefits in accuracy, productivity, insights, compliance and cost savings.

With deep expertise in AI and OCR technologies, Beyond Key’s solutions can help manufacturers maximize the potential of OCR.

However, careful planning is needed to address limitations like legacy document quality, multilingual requirements etc. Partnering with specialists can fast-track adoption in OCR for manufacturing.

The bottom line? OCR is now a mission-critical technology for optimizing manufacturing operations and harnessing information assets. Implementing enterprise-wide OCR in manufacturing promises to be a pivotal step in digitally transforming document workflows.

There are a few specific types of OCR technologies suited for manufacturing:

There are a few specific types of OCR technologies suited for manufacturing: