Manufacturing Dashboards

Track & monitor production KPIs and get notified about equipment downtime in real-time to maximize production efficiency with manufacturing dashboards for every situation

Book a free demo

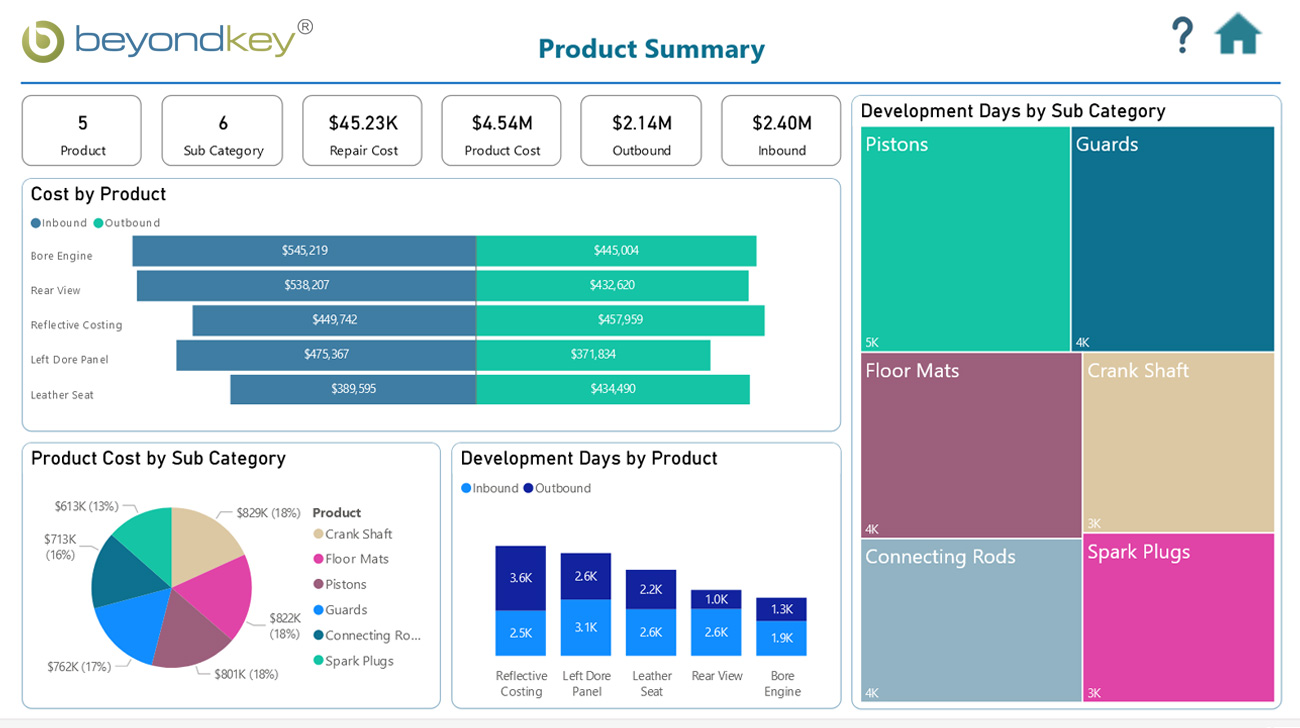

Beyond Key provides custom manufacturing dashboard views that are highly-informative and easy to configure so you can track key metrics and important KPI associated with your day-to-day manufacturing operations & processes.

Manufacturers working into various sectors are collecting extensive amount of data related to various activities happening on the factory floor, records related supply chain, readings from IoT devices, etc.

Using Power BI manufacturing dashboards, you can harness the true potential of this data and utilize it for predictive decision making into identifying defects, streamlining supply chain operations, or even determining the likelihood of possible breakdowns.

Manufacturing is a complex process that depends on various factors, such as the skill of operators, productivity, capacity, workforce, production volumes, planning, and contingency. Each of these factors needs to work in harmony to ensure that the manufacturing process runs smoothly.

Fortunately, dashboards provide a practical solution for tracking not only each of these factors but also how they relate to one another.

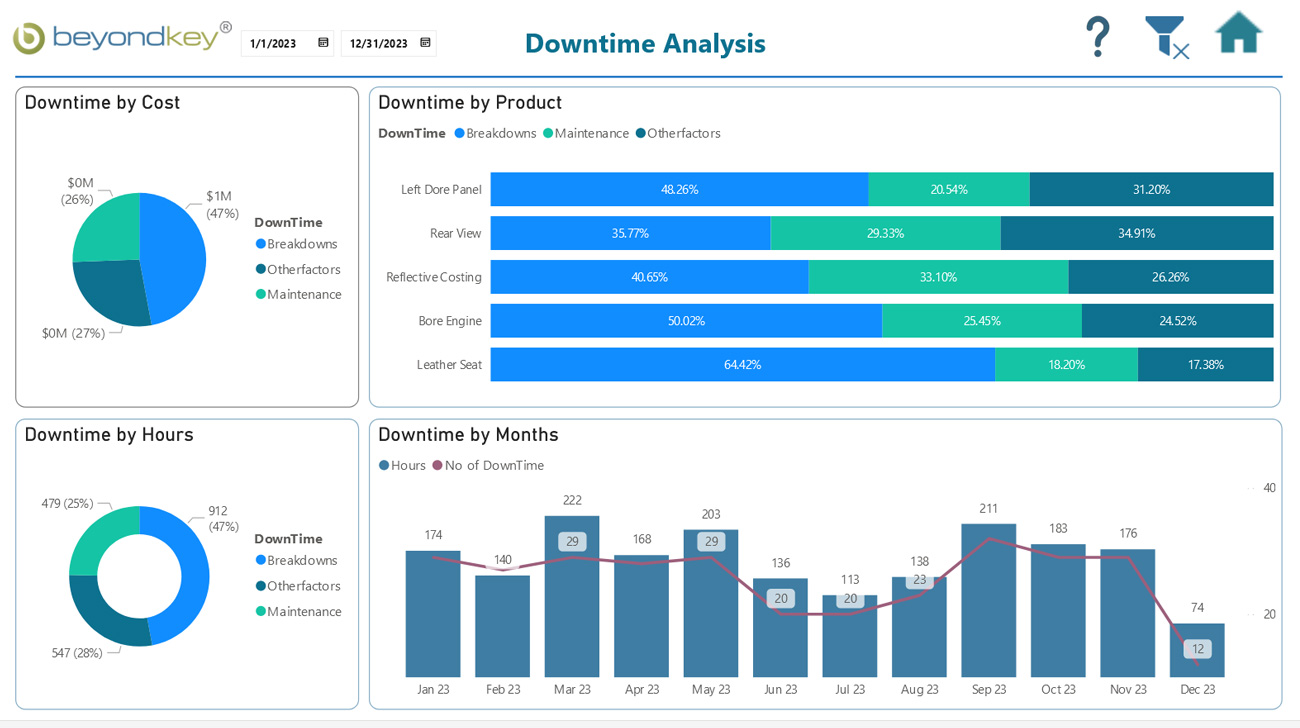

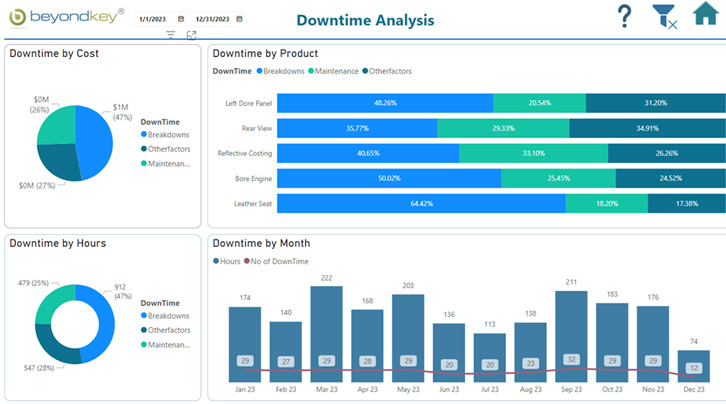

Analyze data to identify various patterns associated with unplanned downtime due to asset failure, supply chain issues, and other unforeseeable events and reduce losses in your business.

Aberdeen Strategy & Research estimated that the average hourly cost of downtime for manufacturing business owners was US$260,000 in 2016 – up 60% from 2014.

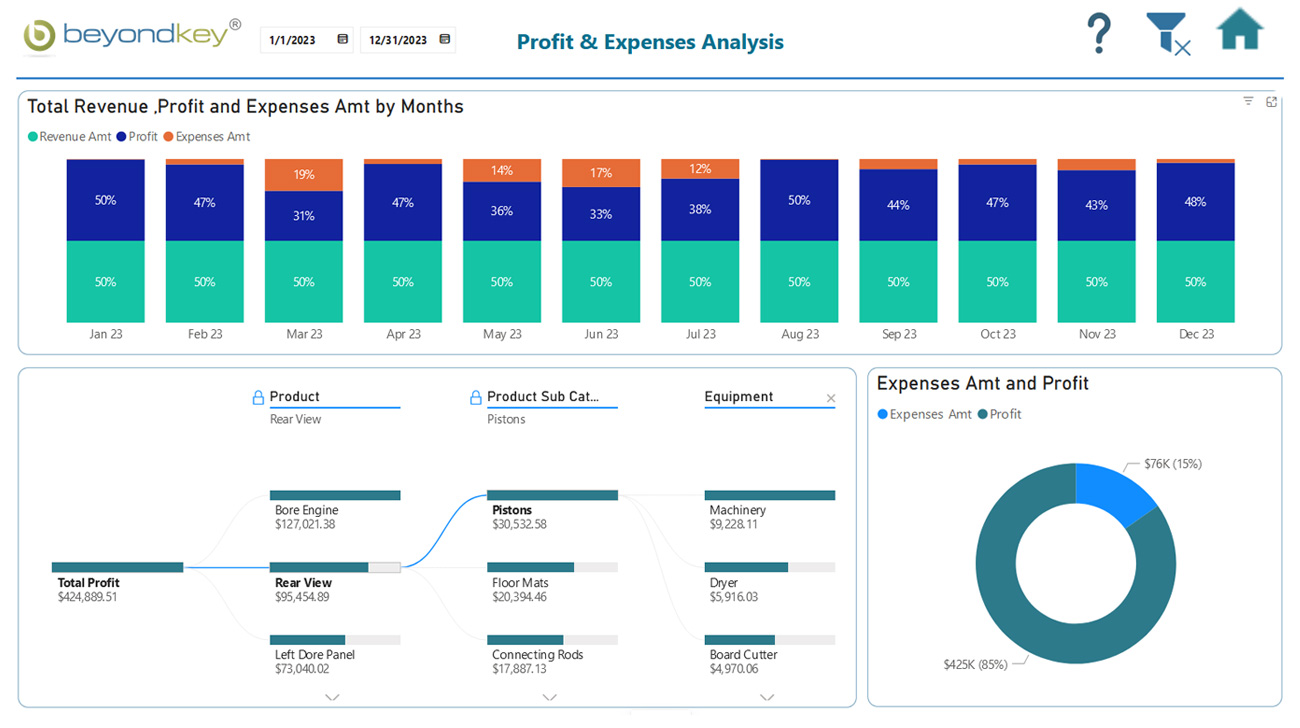

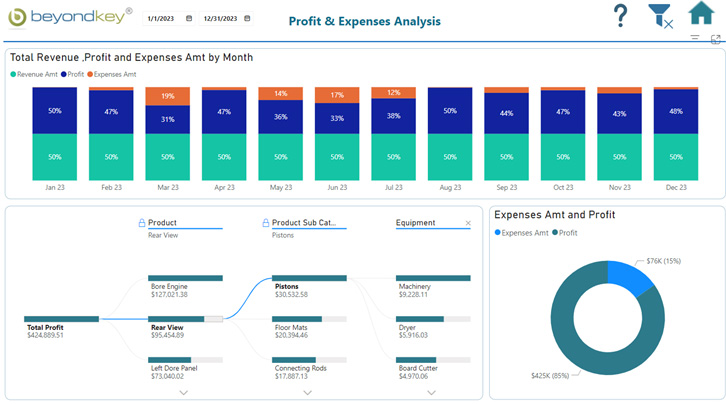

Trend analysis utilizes predictive intelligence to forecast upcoming sales patterns backed by historical data from various production processes, from inventory management to sales and marketing operations.

Thus, helping manufacturers gain statistical data to take data-driven decisions to reduce costs and boost profits

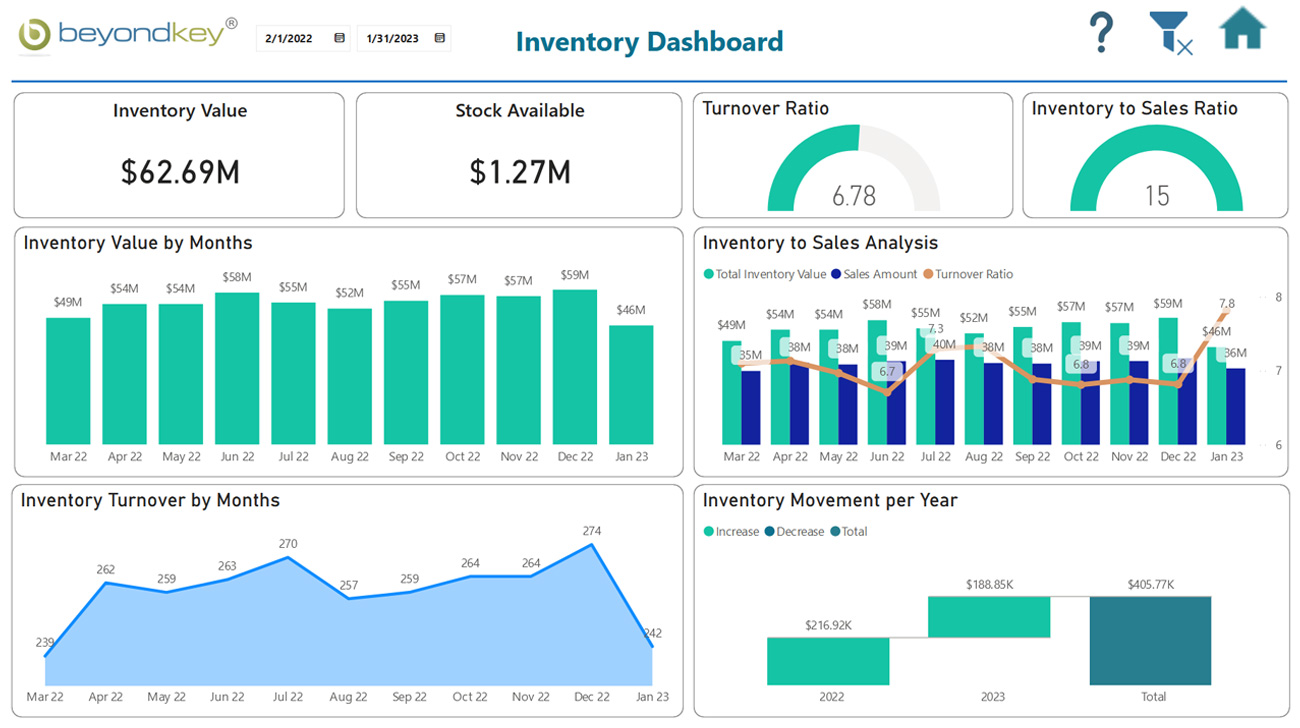

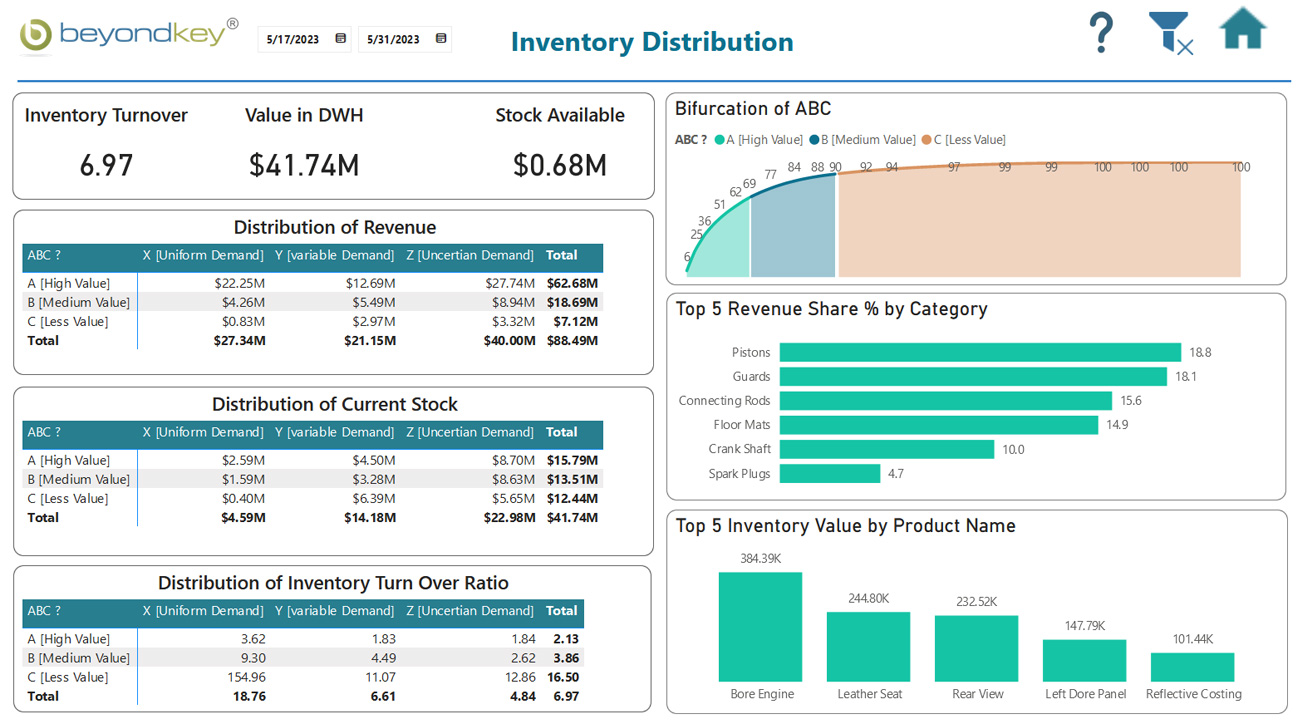

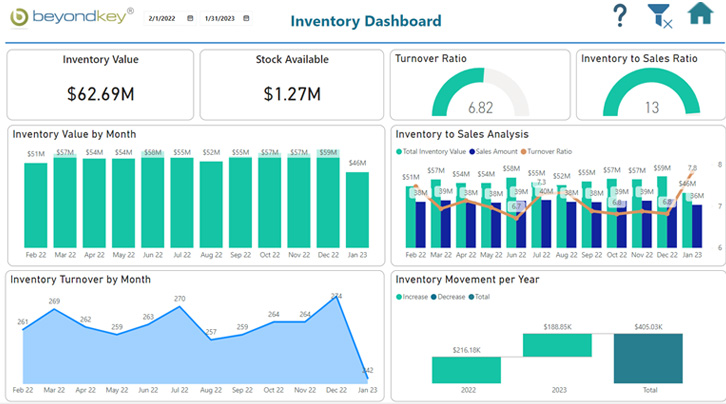

Proper inventory management ensures that goods are available to meet consumer demand without the need for overstocking. This helps you scale your production accurately while avoiding wastage, which leads to an increase in profits.

Download our recent case study where we helped a Canada based manufacturer of architectural hardware products

improve their sales, orders, accounting, and inventory datasets using manufacturing dashboard.

According to the Mckinsey Global Institute, manufacturing is the most data-prolific industry which on average generates 1.9 petabytes of data every year.

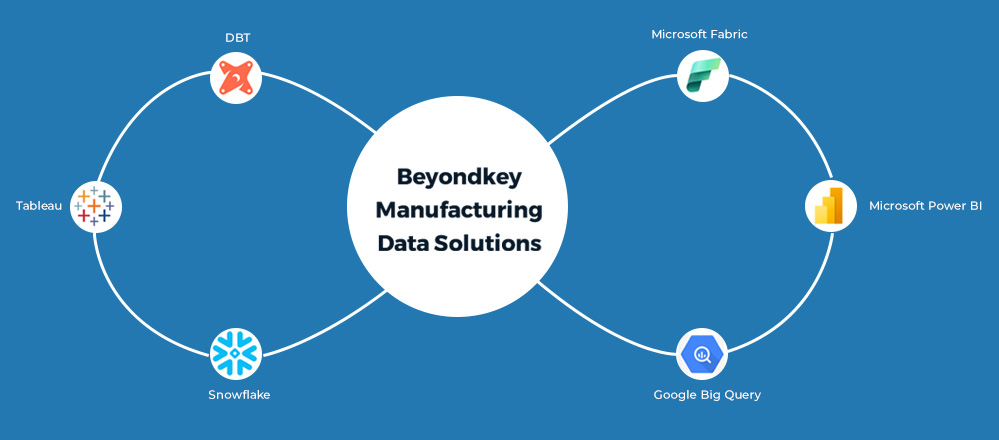

With petabytes of data curated every year manufacturers need to align a formidable data management strategy backed by modern data management platforms like Snowflake & Microsoft Fabric.

If you are ready to unlock Industry 4.0, Beyond Key’s manufacturing dashboards are here. Our AI-powered transformation boosts productivity, optimizes decisions, and creates an agile IT backbone for smart manufacturing.

Looking for Digital Transformation?

INDIANA:

201 N Illinois Street,

16th Floor - South Tower

Indianapolis, IN 46204

United States

ILLINOIS:

405 W

Superior St, 707

Chicago, Illinois 60654

United States

Email us for Business

Call Us

AUSTRALIA:

Unit 605,

354 Church Street

Parramatta, Sydney, NSW 2150

Australia

Email us for Business:

Call Us

Indore Office:

NRK Business Park,

901 A, PU4, Scheme No. 54, Vijay Nagar,

Indore,

Madhya Pradesh 452010,

India

Pune Office:

Nyati Empress,

Awfis, 9th Floor, Off Viman Nagar Road,

Viman Nagar,

Pune, Maharashtra 411014,

India

Hyderabad Office:

N Heights,

Level 6, Plot No. 38, Phase 2, HITEC City,

Hyderabad, Telangana

500081,

India

Email us for Career:

Email us for Business:

Call Us